CAS 301-02-0 Oleamide Factory in China

Nature

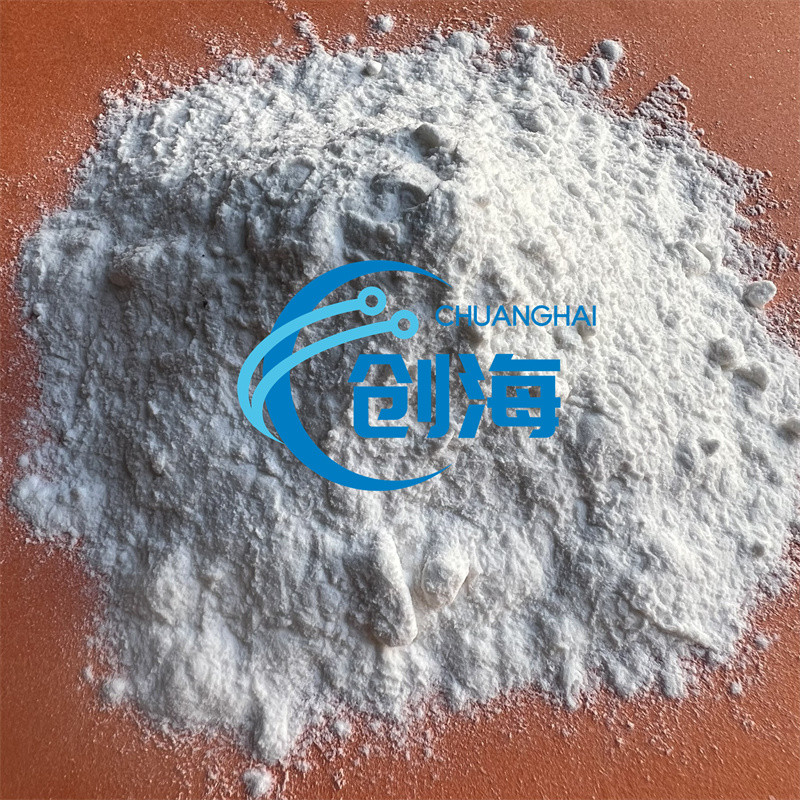

| Product name | Oleamide | CAS No. | 301-02-0 |

| Appearance | White powder | Specification | 99% |

| Origin | China | Brand | Hebei , China |

Nature

| Melting point | 70°C |

| Boiling point | 433.3±24.0 °C(Predicted) |

| density | 0.94 g/cm3 |

| storage temp. | -20°C |

| solubility | Soluble in chloroform (50 mg/ml), ethanol (100 mM), DMSO (~14 mg/ml), and DMF (~14 mg/ml) |

| pka | 16.61±0.40(Predicted) |

| form | neat |

| color | White to off-white |

| Water Solubility | Insoluble in water. |

| Stability: | Stable for 2 years from date of purchase as supplied. Solutions in DMSO or ethanol may be stored at -20°C for up to 1 month. |

| InChIKey | FATBGEAMYMYZAF-KTKRTIGZSA-N |

| LogP | 6.882 (est) |

| CAS DataBase Reference | 301-02-0(CAS DataBase Reference) |

| NIST Chemistry Reference | 9-Octadecenamide, (z)-(301-02-0) |

| EPA Substance Registry System | Oleamide (301-02-0) |

Description

Oleamide is a high purity, fast blooming chemical, suggested as a slip additive in Polyolefin applications. It reduces CoF between the layers of the film and also between the film and other surfaces which are in contact with film. A very small use level of 0.1% it will impart required slip properties to Polyolefin films used for high speed packaging applications. It is used in printing inks, rubber compounds, adhesives, coatings, closures and EVA co-polymers as a surface lubricant in production of metal articles. It also improves penetration, flexibility and slips and seal properties of wax and resin coated paper and paperboard products.

Function

It is used in printing inks, rubber compounds, adhesives, coatings, closures and EVA co-polymers as a surface lubricant in production of metal articles. It also improves penetration, flexibility and slips and seal properties of wax and resin coated paper and paperboard products.

Application of Oleamide(ODA)

Oleamide is a high purity, fast blooming chemical, suggested as a slip additive in Polyolefin applications. It reduces CoF between the layers of the film and also between the film and other surfaces which are in contact with film. A very small use level of 0.1% it will impart required slip properties to Polyolefin films used for high speed packaging applications. It is used in printing inks, rubber compounds, adhesives, coatings, closures and EVA co-polymers as a surface lubricant in production of metal articles. It also improves penetration, flexibility and slips and seal properties of wax and resin coated paper and paperboard products.

description1